Previous Page

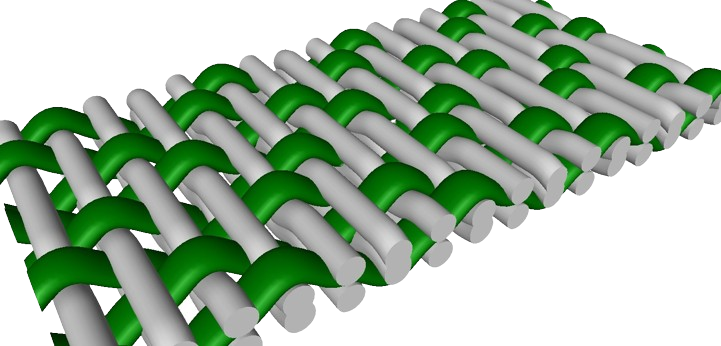

WOVEN DRYER SCREENS

Twin Plane-H Dryer Screens

Shaimar Wires has optimized dryer fabrics for durable and reliable performance even uder challenging conditions

which minimizes the unexpected, unplanned Dryer Fabric changes reducing the downtime significnatly. Shalimar

Wires always strive to offer reliable, optimized and cost-effective solutions to its customer base.

Application

- Low CFM Twin Plane is suitable for initial groups &

Higher CFM on later dryer groups of conventional

dryer section of paper machines producing

writing-printing & Low GSM grades

- Twin Plane H with high CFM & high Caliper is

suitable for higher grammage grades like kraft,

grey board & duplex board.

Features

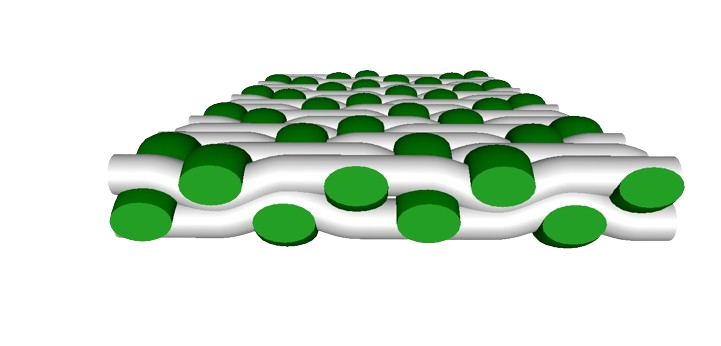

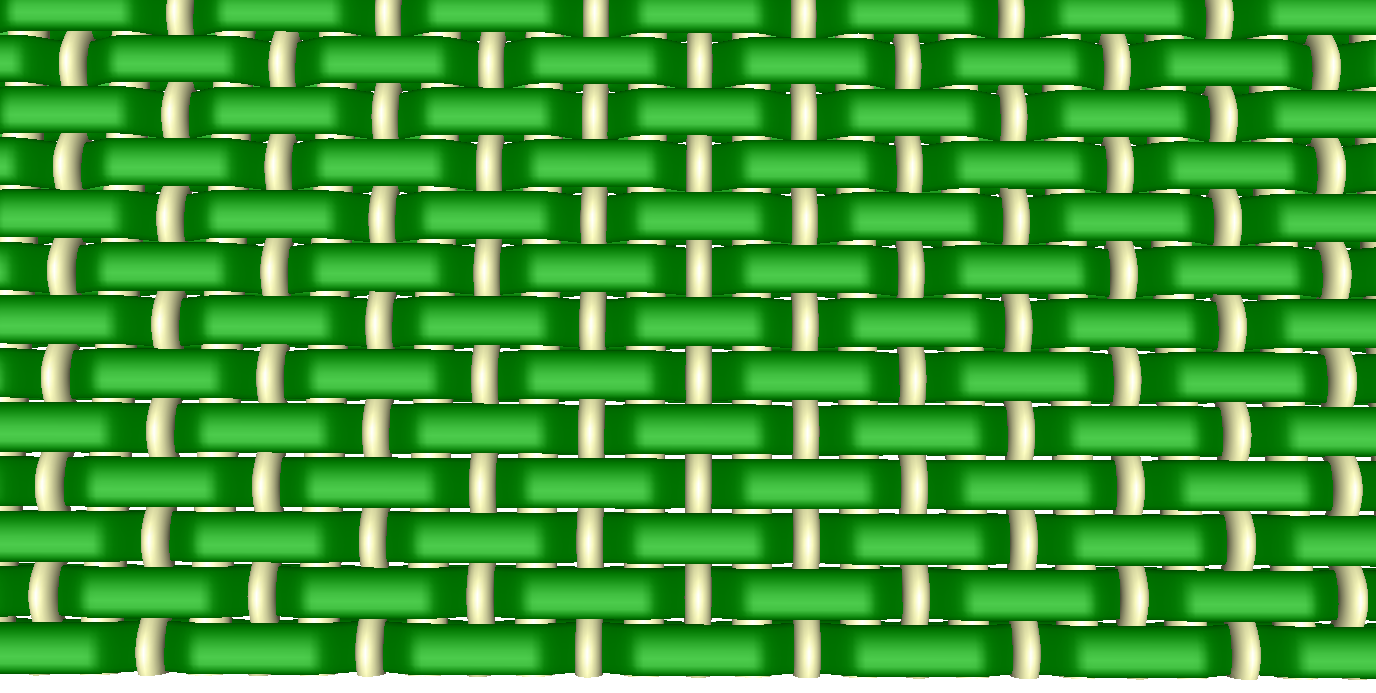

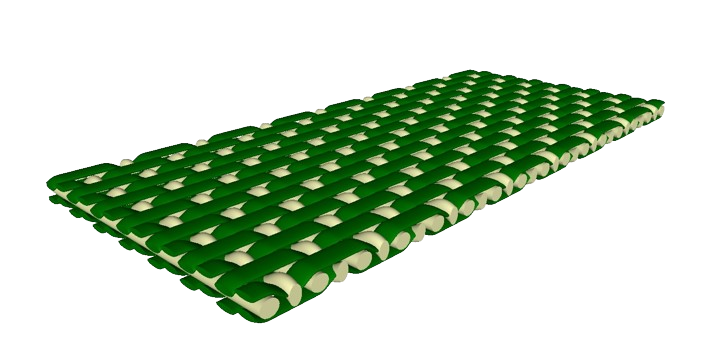

- Double layer construction

- Hydrolysis resistant monofilament flat yarns

- More void, low to high Air Permeability.

- Flat top structure

- Double density pin spiral seam.

- High caliper.