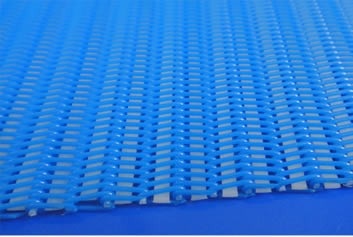

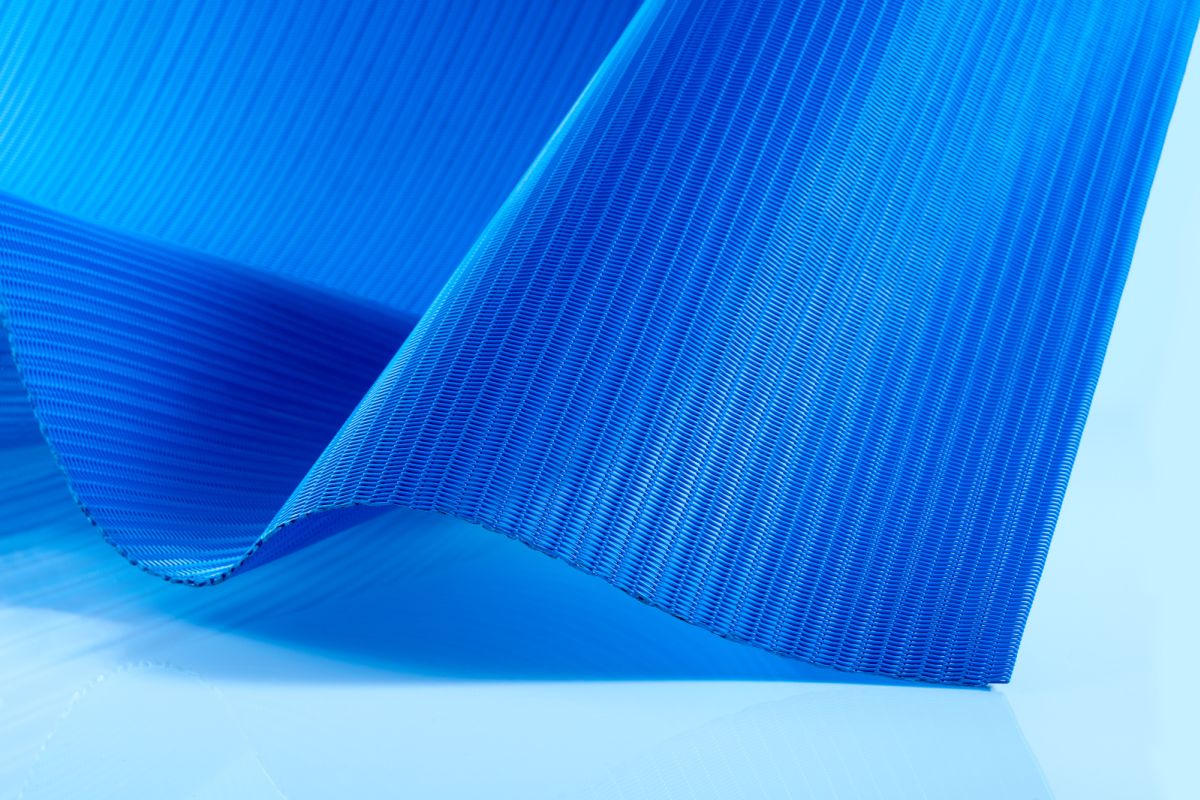

Stuffed Spiral screens for De-watering, conveyor applications

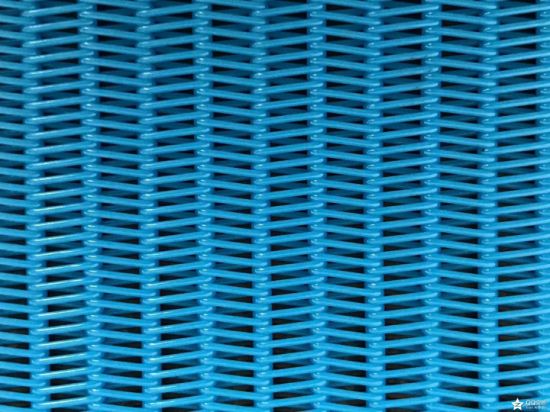

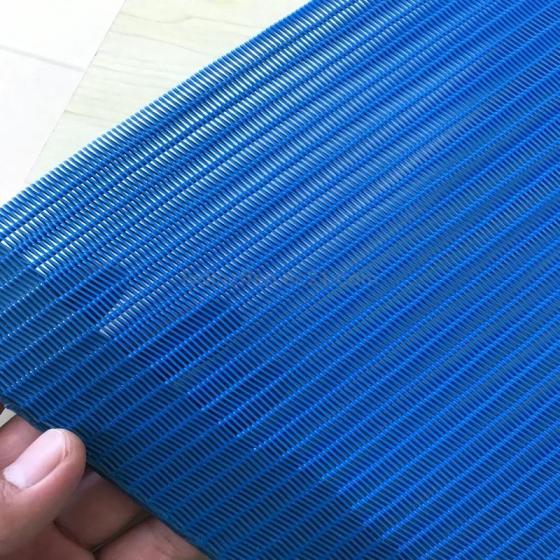

Within a spiral and between two connecting channels, another channel forms, which is called filling channel. To

reduce the air permeability filler wires are inserted into these remaining cavities.

Because of this, the unfilled spiral screens have higher air permeability than filled spiral screens. The value of air

permeability in stuffed spiral screens depends on the size of the cored wire used.

Application

- Drying section.

- Sludge press.

- Slurry De-watering.

- Conveyor belt..

Features

- Stable runnability.

- High Stiffness

- Flat, homogeneous & even surface.

- High Stiffness